Home > Cable Assembly

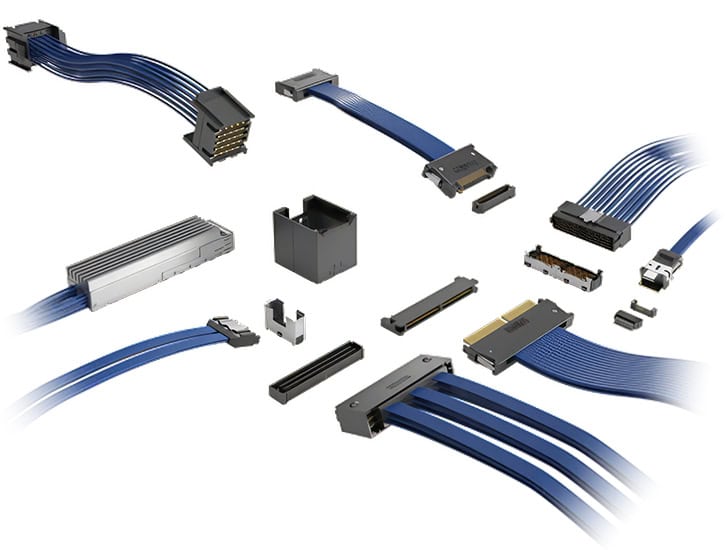

LHD Cable Assembly Manufacturer

We offer customization, quality control, and technology integration that make us the best cable assembly supplier. To meet customer requirements we employ state-of-the-art technologies such as SMT and THT for the manufacturing of cable assemblies. Reliability is evident due to our quality assurance policies that include AOI and X-ray machines. We incorporate the use of technology in our production process, including the use of SPI detectors and automatic printers. This makes our cable assemblies of high quality. Quality and innovation are two very important aspects that define us in the cable assembly industry. We aim for the best. This makes us special. Customers enjoy our great products. That’s our vision as Cable assembly manufacturers.

LHD Mission

We are very keen on the needs of our customers.

LHD Purpose

To provide clients with a truly one-stop shopping experience.

LHD Specialties

To achieve excellent PCBA function.

Each process has inputs and outputs, i.e. relevant documents need to be compiled to guide the production of the corresponding process, such as the wire down table to guide the wire down crimping process.

Note: the wire down table that is, the wire down, crimping details, including a variety of process parameters and requirements, such as process forms. In the wire harness production process, the down wire table ultimately through the down wire crimping process card, used to guide the operation of the down wire crimping process, to guide the workshop production process.

Each process also needs to be inspected, and only after the inspection is passed can the batch be carried out, and the process needs to be monitored at any time. For example, in the next line process, you need to make the first piece, the first piece of wire length, stripping head and other parameters through the inspection, before the batch off the line.

What Are The Key Advantages Of Our Cable Assembly!

High-Quality Materials

Our custom cable assembly uses FR-4, Rogers, and aluminum base materials. FR-4 is durable and reliable. Rogers offers high-frequency performance. Aluminum provides excellent thermal conductivity. Each cable is tested for reliability. We ensure top quality.

Advanced Technology

We use SMT and THT methods in our assembly. SMT (Surface Mount Technology) and THT (Through-Hole Technology) improve connections and performance. SMT offers compact and reliable assemblies. THT provides stronger mechanical bonds for components. Each cable meets world standards. Cable assembly manufacturers use the best tech.

Custom Solutions

Our team makes special solutions for each project. LHD supports customizations in rigid-flex and multilayer boards. These include design, material selection, and testing. Each custom cable assembly is unique.

Efficient Production

We have lines making 52M mounts per month. The fast 0.15-sec chip placement ensures quick work. Each step is smooth. This makes production fast. Cable harness assembly speeds up work. We have the conditions for fast delivery because customers care more about delivery.

Comprehensive Testing

Each cable undergoes SPI, AOI, X-ray, and functional tests to ensure top quality and reliability. SPI checks solder paste, AOI inspects assembly, X-ray checks internal connections, and functional tests confirm performance. We guarantee optimal performance. Cable assembly manufacturers ensure this.

Downstream (material) process

Definition

The so-called underline is according to the design drawings, the different specifications of the wire conductor according to the process documents for cutting, stripping, bundling process.

Process

prepare materials → adjust equipment → first piece of inspection (measuring wire length, stripping head) → mass production (in the final inspection, 100% self-inspection) → finishing wire → to be turned over.

Inspection

The wire length, full stripping and half stripping length, opening length and other process parameters need to be measured in the downstream process.

Crimping Process

Definition: The so-called crimping is the process of acting the wire and terminal together.

Process: ready materials → adjust the equipment → do the first piece → the first piece of inspection (micrometer to measure the height of the crimp, crimp width) → mass production (in the end of the inspection 100% self-check crimp quality) → to be turnover

Inspection: The crimping process needs to measure whether there is R angle, whether the visible range of core wire and insulation skin is within the tolerance range, whether there is any damage to the pressing part of the core wire and insulation skin, and whether there is any damage to the pressing part of the core wire and insulation skin, as well as the crimping distortion degree and other process parameters.

Key Features of Our Custom Cable Assembly

High Precision Manufacturing

Flexible Design Options

Efficient Production Process

Cable Assembly

In PCBA processing, not only is there only component placement, but there are also often a lot of circuit boards that need to be soldered with a large number of wiring harnesses. Generally this harness is used in the DIP insertion process, which is different from other parts of SMT processing, as it needs to be manually inserted into the through-hole and then coated with solder paste through wave soldering.

In the production of PCBA, the wire harness plays an important role in connecting various components and parts. A wire harness is an assembly of multiple insulated wires or optical fibers used to transmit electrical signals, power or data. In PCBA production, wire harnesses assume the following roles:

01

Feeding Wire

Wire feeding equipment: the required processing wire to the transit feeder frame.

Required equipment: wire feed frame, wire feeder.

Requirements: Pay attention not to scratch the surface of the wire. Avoid multiple wire processing at the same time, the wire tension is not the same.

02

Cutting

Cutting:To get the required length, we need to use the wire cutting machine

equipment: computer wire cutting machine, multi-functional cutting line, cutting line stripping machine.

Process: To make sure that the wire is up to standard, we have some standards in the production process. It is not allowed to cut the surface of the wire; not allowed to cut the copper wire; it is not allowed to strip the length of the wire with an error of more than ±1mm.

03

Stripping

Wire stripping: according to the SOP requirements strip the length of the wire at the connector corresponding to the insulation.

Equipment: Machine for wire cutting, vertical stripping, and pneumatic stripping

Process requirements: no surface crush; peeling length error is not allowed to exceed ± 1mm.

04

Twisting line

Twisted wire: finishing and twisting the conductor at the joint.

Required equipment: cutting line stripping and twisting machine, cutting line twisting machine.

Craft requirements: not allowed to scratch the surface of the wire; copper wire must be twisted tightly, and not allowed to appear loose wire.

Equipment: The equipment required for Step 4 is the same as the Step 3

Process requirements: no surface crush; peeling length error is not allowed to exceed ± 1mm.

05

Crimp Terminal

Rivet terminals: riveted joints at the conductor and plug terminals.

Required equipment: terminal machine, single and double head terminal machine, automatic terminal machine, copper tape machine, mute terminal machine.

Process requirements: the terminal is not deformed and must meet the requirements of tension, riveting height, width.

06

Dip Tin

Dip tin: tin on the joints to facilitate the insertion of circuit boards.

Required equipment: automatic tin machine, single and double head tin machine, cutting line tin machine.

Process requirements: tin evenly, not allowed to not appear loose wire, tin depth in line with the requirements.

07

Assembly

assembling plastic plug shell.

Required equipment: electric screwdriver.

Requirements: screws are not allowed to expose the surface of the plastic shell; must meet the product requirements of the torque.

08

Conduction Test

the use of instruments for wire harness conduction test.

Required equipment: conductivity tester.

Requirements: no short circuit, broken circuit, miswiring, poor contact, poor insulation and other phenomena.

09

Packaging

use plastic bags to encapsulate the finished wire harness and put it into carton.

Required equipment: sealing machine and baler.

Requirements: sealing should be flat; packing tape should be tightly wrapped carton, not allowed to fall off.

Some Successful Cases of Our Company

Medical Device Cable Assembly

In 2023, LHD built 5,000 medical device cables in our San Francisco plant. They included FR-4 boards and precision connectors. The team met IPC-A-610 standards. This cut assembly time by 20% using automated wire-cutting machines. This assembly solved connectivity issues in medical devices.

Industrial Control Systems

LHD made 6,000 industrial control cable assemblies in 2022 at our Texas location. These used aluminum baseboards and tough connectors. Automated tests ensured a 99.5% defect-free rate. This improved efficiency by 25%. Cable assembly manufacturers helped solve control system issues.

Consumer Electronics Wiring

In 2020, LHD made 12,000 consumer electronic cables in our Florida factory. These had rigid-flex boards and multi-layered connectors. The project used AOI for quality checks. This reduced production costs by 10%. Custom cable assembly solved wiring issues in consumer electronics.

Pre-assembly (Pre-Assembly) Process

Definition

The so-called pre-assembly is the process of assembling the semi-finished products with sheaths, tubes, rubber parts and other components into new semi-finished products after wire or crimping.

Procedure

Prepare all the materials → one insertion, two listening, three pull back → installation of self-locking

Inspection

According to a plug two listen to three back to pull the process to complete the self-inspection.

Assembly (Total Assembly) Process

The so-called assembly is the process of combining the semi-finished products after wiring or crimping, semi-finished products after pre-assembly and other materials into a finished wire harness. Tape or zip ties are bundled into bundles, which are wire harnesses.