-300x300.jpg) What’s FR-4 material?

What’s FR-4 material?

FR-4 material, which is the abbreviation of fiberglass cloth, the full name of FR-4 is “flame retardant”. It means a material that does not spread flames and meets UL94V-0 flame retardant standards. It is a commonly used raw material and substrate for circuit boards, and the code of the flame retardant material grade, which means that the resin material must be able to self-extinguish after being burned. It is most commonly used in PCBs (printed circuit boards), and general single-sided, double-sided, and multi-layer PCB circuit boards are made of this! Due to its high strength and flame retardancy, most PCB manufacturers will choose FR-4 as the substrate.

FR-4 is just a general term for a class of plates. The fiberglass cloth is an electronic grade fiberglass woven into a thin, cloth-like material. Fiberglass gives FR-4 the necessary structural stability. This fiberglass cloth is surrounded and bonded with an epoxy resin containing flame-retardant additives. Resins give materials rigidity as well as other physical properties.

Types of FR-4 material

There are 5 types of FR-4: Standard FR-4, High Tg FR-4, High CTI FR-4, Halogen-Free FR-4, and Copper-Free FR-4.

The wide range of applications of FR-4 material

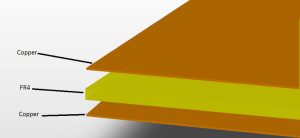

FR-4 material is often used in the production of printed circuit boards (PCBs). A thin copper roll is usually laminated to one or both sides of the FR-4 glass dioxide panel. These are often called copper-clad or laminated

FR-4 is also used in the construction of bus bars, transformers, relays, switches, gaskets, stops, arc shields and screw terminal strips.

Why choose FR-4?

Why choose FR-4?

- Low Cost: FR-4 PCB materials cost less than most other options (such as metal substrates). This makes it an attractive choice for most PCB types, from basic designs to complex multi-layer boards.

- Excellent Mechanical Strength: FR-4 PCB is a sturdy circuit board that can accommodate heavy-duty components. In addition to this, In addition, it is rigid enough to be used in harsh conditions.

- Non-flammable: The FR94 circuit board has a flammability rating of UL0-V4 and does not spread fire in the event of an accident, which makes it a safe material choice.

- Moisture Resistant: FR-4 boards are resin-bonded to resist moisture and have near-zero absorption. So you can use it in humid conditions and you don’t have to worry about its usage.

FR-4 also has its limitations. For example, due to its low thermal conductivity, it cannot effectively dissipate heat. Its dielectric constant also changes at higher frequencies, which may not be suitable for the need for controlled impedance.

FR-4 alternatives include aluminum and other metal PCBs, ceramics, and polyimides, particularly in flexible circuit boards and CEM (composite epoxy materials).

Conclusion

Overall, FR-4 material is a versatile and reliable material that combines electrical insulation, mechanical strength, and thermal stability. Its unique properties make it ideal for a variety of electronic applications ranging from consumer electronics to industrial automation systems. As technology continues to advance, FR-4 materials will likely remain a key component in producing the high-quality PCBs that power the devices we rely on every day.