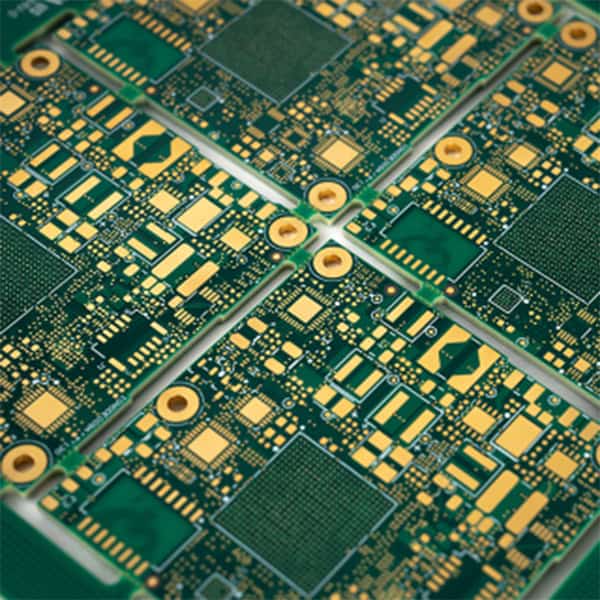

Surface Finish

The following is an introduction to several common PCB surface treatments from LHD Technology and their advantages and disadvantages:

PCB surface treatment is a key process to ensure the performance and reliability of the circuit board. Its main purpose is to protect the bare copper surface from oxidation while providing good solderability to achieve reliable connections when assembling electronic components.

HASL (lead-free tin spraying)

HASL is the most common and economical choice. The PCB is immersed in molten solder, and then the excess solder is removed with a hot air knife.

The general process of automated production is: micro-etching → preheating → flux coating → tin spraying → cleaning.

Advantages: low cost, strong oxidation resistance, good welding performance.

Disadvantages: thermal shock, not suitable for plated through holes (PTH), poor wettability, uneven surface, not suitable for fine pitch components.

Immersion Silver (IAg)

Immersion Silver (IAg) is a popular surface finish used in the manufacturing of printed circuit boards (PCBs). This process involves applying a thin layer of silver to the exposed copper pads of a PCB, providing excellent solderability and protection against oxidation.

Advantages:Cost-Effective,Excellent Solderability,Flat Surface,Environmental Compliance,Multiple Reflows,Good Conductivity

Disadvantages:Tarnishing,Limited Shelf Life,Handling Sensitivity

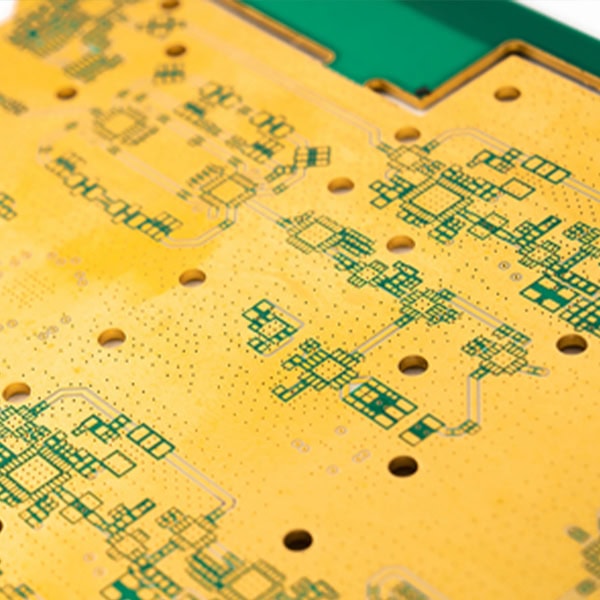

Hard Gold Plating

PCB electroplating (Hard Gold Plating) is a surface treatment process that deposits a metal layer on the surface of a printed circuit board (PCB). This process forms a hard metal layer on the surface of the PCB copper foil through electrochemical deposition.

Advantages: good wear resistance, suitable for frequent plugging and unplugging occasions, strong corrosion resistance, can prevent surface oxidation, good conductivity, conducive to electrical signal transmission, good welding performance

Disadvantages: high cost, complex process, requires multiple steps, certain environmental risks

Lead-free tin spraying is an environmentally friendly process, similar to traditional HASL, but using lead-free solder, which has very little harm to the earth’s environment and human body, and is also a process advocated at this stage. The lead content in lead-free tin spraying does not exceed 0.5, and the melting point of lead-free tin is high, so the welding point is much stronger.

Advantages: environmental protection (RoHS compliant), good welding performance.

Disadvantages: high cost, insufficient flatness.

Lead-free hot air soldering leveling (LF HASL)

The general process of automated production is: micro-etching → preheating → flux coating → tin spraying → cleaning.

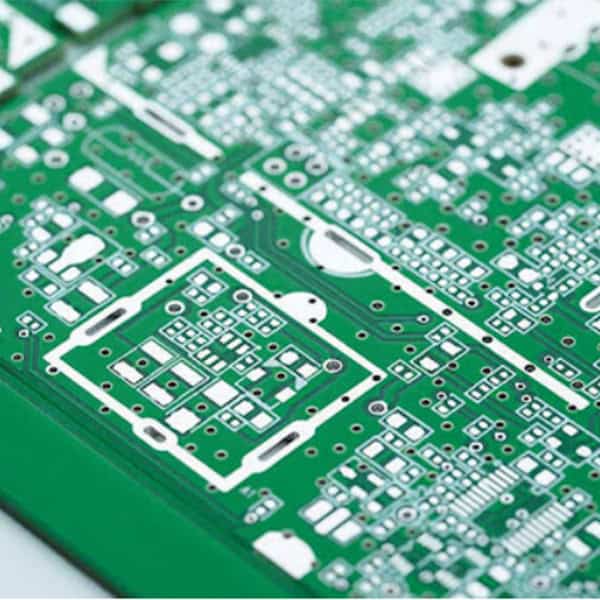

ENIG (Electroless Nickel/Immersion Gold)

The general process flow is pickling cleaning → micro-etching → pre-immersion → activation → chemical nickel plating → chemical leaching.

Immersion gold (ENIG) is a widely used surface treatment process in printed circuit board manufacturing, known for its excellent solderability, corrosion resistance and flat surface characteristics. This double-layer coating consists of a layer of electroless nickel and a thin layer of immersion gold, which can effectively prevent oxidation and improve the reliability of solder joints.

Advantages: High flatness, providing a very flat soldering surface, suitable for fine pitch components.Long shelf life, with good storage performance.

Disadvantages: High cost, ENIG is more expensive than other processes.Black disk effect, the nickel layer may oxidize, causing soldering problems.

Immersion Tin (ISn) is a surface treatment process widely used in printed circuit board (PCB) manufacturing. The process deposits a thin layer of tin on the copper surface of the PCB through a chemical replacement reaction, providing excellent solderability and oxidation resistance.

Advantages: good solderability, oxidation resistance protection, flat surface, environmental protection

Disadvantages: tin whisker problem, handling sensitivity, short shelf life

Immersion Tin (ISn)

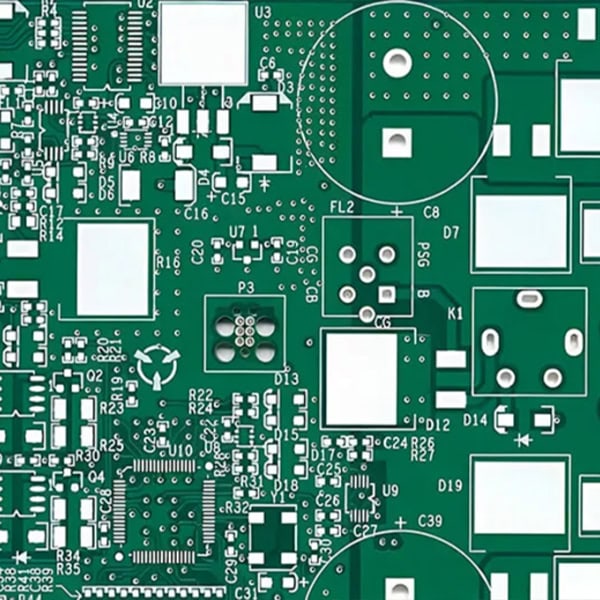

OSP

Organic Solderability Preservatives (OSP) is a technology used for printed circuit board (PCB) surface treatment, designed to protect the bare copper surface from oxidation while maintaining good soldering performance.

Advantages: low cost, good solderability, good flatness, environmentally friendly

Disadvantages: film is easily damaged, short storage time, not suitable for multiple reflow soldering, difficult to detect