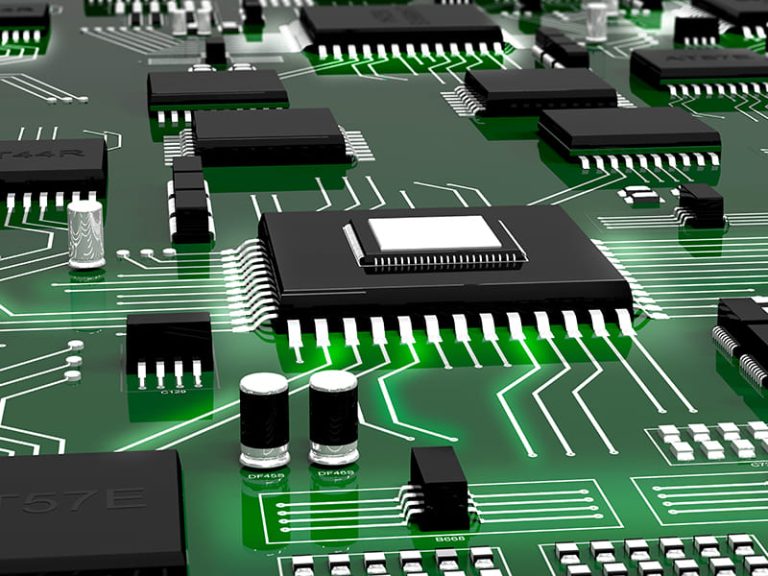

In the ever-evolving world of electronics manufacturing, ensuring the quality and reliability of printed circuit boards (PCBs) is crucial. As devices become more complex, with denser component placements and intricate circuitry, traditional testing methods sometimes fall short. This is where the flying probe enters as a sophisticated, versatile solution that has become an industry favorite for PCB testing.

Table of Contents.

ToggleWhat is Flying Probe Testing?

Flying probe testing is a type of in-circuit testing (ICT) that uses multiple moving probes to test the electrical performance of PCBs. Unlike traditional ICT, which requires a custom-made bed-of-nails fixture, this testing employs a set of robotic probes that “fly” over the board. These probes make direct contact with test points, component pads, and vias to check for short circuits, open circuits, component values, and signal integrity.

The lack of a dedicated fixture gives this method a significant advantage in terms of flexibility. As electronics manufacturers continually push for shorter product development cycles, the ability to test boards without needing a specific setup is a game-changer. It enables rapid prototyping and quicker turnarounds, which are vital in today’s fast-paced market.

How Does Flying Probe Testing Work?

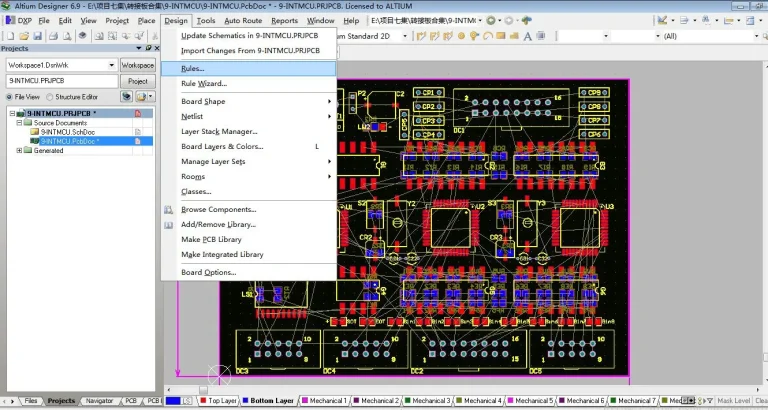

Flying probe testers typically use two to eight probes that move across the surface of the PCB under the control of precise software algorithms. The probes are capable of reaching almost any point on the board, allowing them to perform a variety of tests. The key tests include:

- Continuity Testing: The probes verify that electrical connections between components are as intended, ensuring there are no open circuits.

- Short Circuit Detection: They check for unintended connections between circuit paths that could cause malfunctions.

- Component Verification: This testing can measure resistances, capacitances, and diode junctions to confirm component values and polarities.

- Signal Testing: Advanced testers can generate and measure complex signal waveforms, ensuring the dynamic performance of the circuit.

The Advantages of Flying Probe Testing

- Flexibility: Since this testing does not require a physical fixture, it’s ideal for low- to medium-volume production runs and prototypes. This makes it an attractive option for manufacturers who frequently modify their designs or produce a wide variety of boards.

- Cost-Effectiveness: Developing a fixture for traditional in-circuit testing can be expensive and time-consuming, especially for complex boards. Flying probe testing eliminates the need for these fixtures, reducing both setup costs and lead times.

- Speed: While flying probe testing might be slower than bed-of-nails ICT in high-volume production, it significantly accelerates the testing process for small batches. Manufacturers can perform thorough tests without the delay of fixture creation, allowing for quicker feedback and adjustments in the design phase.

- Precision: Flying probe testers can access incredibly small and dense areas on a PCB that might be unreachable with traditional fixtures. This is particularly important as modern electronics increasingly rely on miniaturized components and complex multi-layer boards.

Applications of Flying Probe Testing

Flying probe testing is widely used in various sectors of the electronics industry, including aerospace, automotive, consumer electronics, and telecommunications. Its ability to handle intricate, high-density designs makes it invaluable for testing prototypes, small production runs, and high-reliability boards where quality cannot be compromised.

For instance, in aerospace electronics, where safety is paramount, this precision testing ensures that each PCB meets stringent quality standards. Similarly, in the automotive industry, this method helps verify that control units and sensors function correctly before they are deployed in critical vehicle systems.

With flying probe testing, manufacturers can keep pace with the demands of innovation, ensuring that their products not only reach the market faster but also perform flawlessly in the hands of consumers.