Laboratory

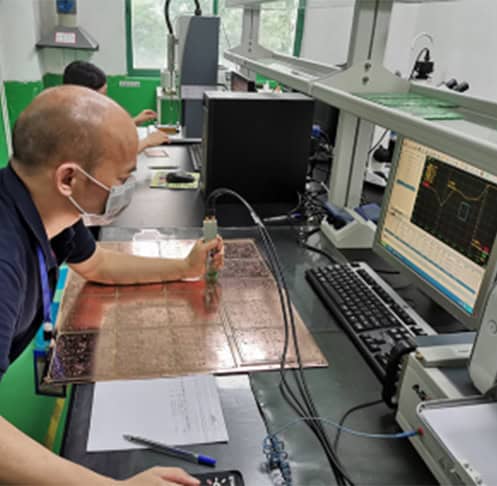

We invest in our lab and your product quality

LHD Technology strictly controls quality in every process of PCB production. Our lab has advanced equipment to better design and control product innovation and quality.

Process development and optimization

Environmental compliance

Customer Support

Material and Product Testing

Material Analysis: The laboratory is responsible for analyzing and testing the materials used in the PCB manufacturing process to ensure that they meet design and environmental standards. This includes composition and performance testing of substrate materials, solder, solder mask, etc.

Failure Analysis: Through various testing methods (such as section analysis, scanning electron microscope observation, etc.), the laboratory can identify and analyze the failure modes of PCBs and their components. This helps to find the root cause of the problem and improve the design or manufacturing process.

Quality Control

Process Monitoring: The laboratory ensures that every link in the production process meets quality standards through regular sampling and testing. This includes evaluation of welding quality, electrical performance, mechanical strength, etc.

Reliability Testing: Environmental and mechanical stress tests such as temperature cycling, vibration shock, salt spray testing, etc. are performed to evaluate the reliability of PCBs under different conditions.