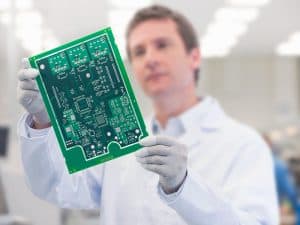

Learn About PCB Assembly Services

PCBA refers to the complete manufacturing process of soldering electronic components to printed circuit boards, covering the entire process from PCB manufacturing, component procurement, SMT/DIP, functional testing to final packaging.

PCBA Production Process

SMT Project | Process Capability |

Production Line | 7 |

PCB Size | L810mm*W490mm~L50mm*W50mm |

PCB Thickness | 0.75mm~4.0mm |

Substrate Material | Hard board, soft board, hard-soft board |

Minimum Component Size | 01005 (English) |

Minimum Component Spacing | 0.25mm (QFP/QFN/BGA) |

Component Height | Maximum 15mm |

Printing Alignment Accuracy | ±0.015mm |

Placement Accuracy | ±0.035mm |

Actual Production Capacity | 7 million points~8 million points/day |

Core links of PCB assembly service process

PCB design and manufacturing

Including multi-layer boards, flexible boards, metal substrates and other types, supporting rapid prototyping (fastest delivery within 24 hours).

Component procurement

Provide BOM list management, reduce costs through centralized procurement, and ensure that components are genuine original products

Patches and plug-ins

SMT: Suitable for micro components (such as BGA, QFN packages), using high-speed placement machines to achieve high-precision production.

DIP: For traditional components, combined with wave soldering or manual soldering.

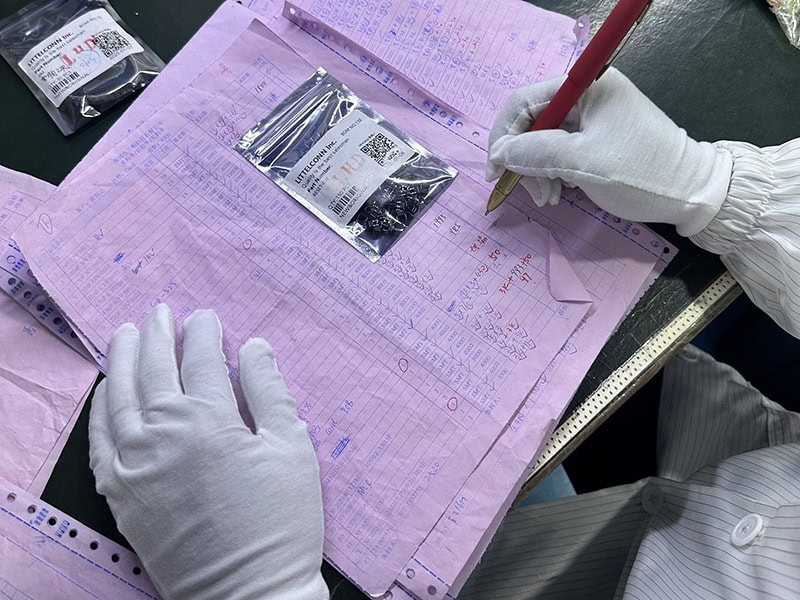

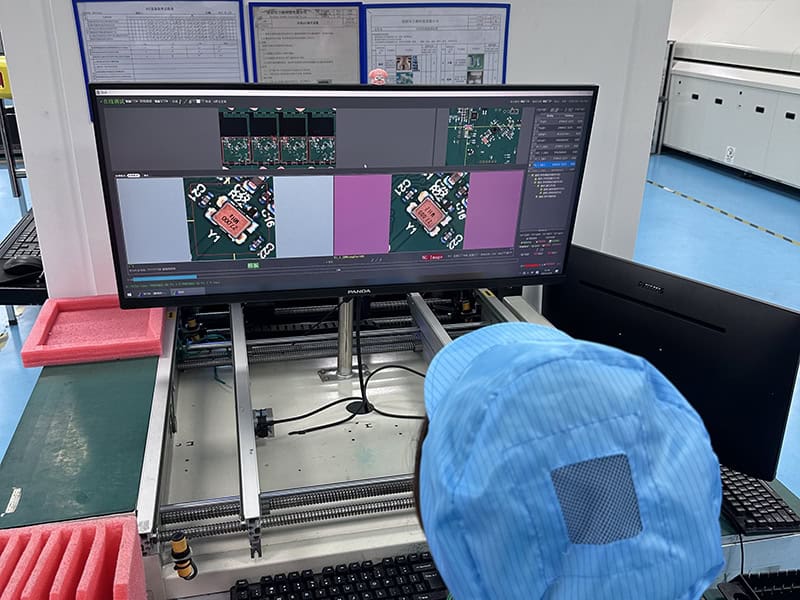

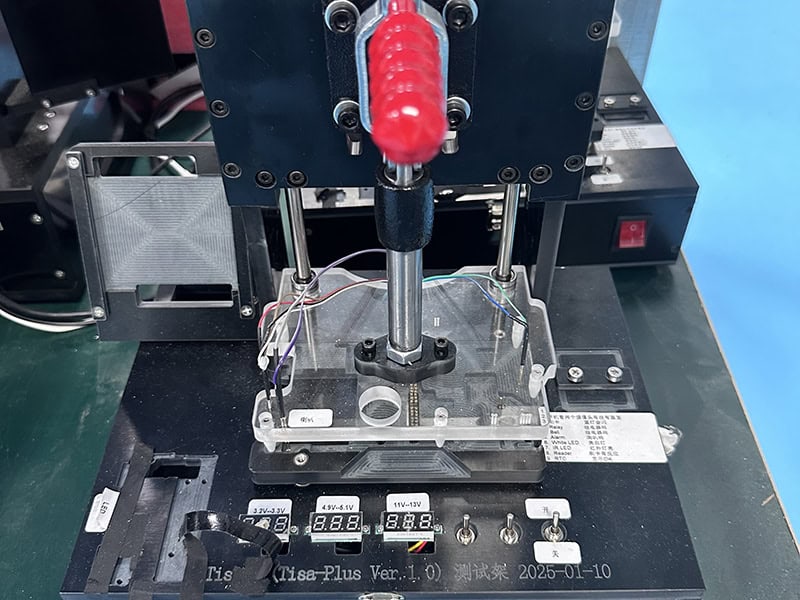

Testing and Quality Assurance

Check the consistency of components with BOM list, PCB appearance and pads

Check solder joint quality, component polarity and position deviation

Detect defects such as voids and cold solder joints in hidden solder joints such as BGA packages

Burn the program to verify that the hardware and software work together

Long-term high-load operation to find defective products

Why Choose Us?

Quick Response

Our production lines are highly efficient, ensuring timely delivery of orders.

Quality Assurance

Our strict quality control process and experienced team ensure that every PCBA meets the highest standards.

Price Advantage

We have a complete supply chain system and strict process system to provide customers with competitive prices

Technical Support

Our engineers and R&D team can provide you with comprehensive technical support to ensure the smooth completion of your project.

our service

SMT Assembly: Our SMT production line uses state-of-the-art technology to ensure high efficiency and precision.

DIP Plug-ins: We provide professional DIP Plug-in services to meet your special needs.

Reverse Engineering: Our team of engineers can help you with reverse engineering and provide technical support for your project.

Purchasing components: We work with reliable suppliers to ensure the quality and supply of required components.

PCBA design: Our R&D team can provide customized PCBA design services according to your needs.

24/7 After-Sales Service: We provide 24/7 after-sales support to ensure your project runs smoothly.

Future development trends of PCB assembly

With the electronic products development, and the trend of miniaturization intensifies, PCB assembly technology will take the following development soon

High-Precision Integration

The integration of components on the PCB will improved, to achieve smaller sizes and higher-performance devices and products.

Artificial Intelligence

Add artificial intelligence, machine study, and technology, to improve the PCB assembly efficiency and quality control level.

Environment energy saving

Use environmental technology and materials, to reduce the impact on the environment.

We should continue to improve the PCB Assembly technology and application, improve our understanding, and study more techniques when we pursue technological innovation. To provide more and more reliable and efficient support for the development of electronic products.