BGA PCB Assembly

Why Choose LHD Technology

01.

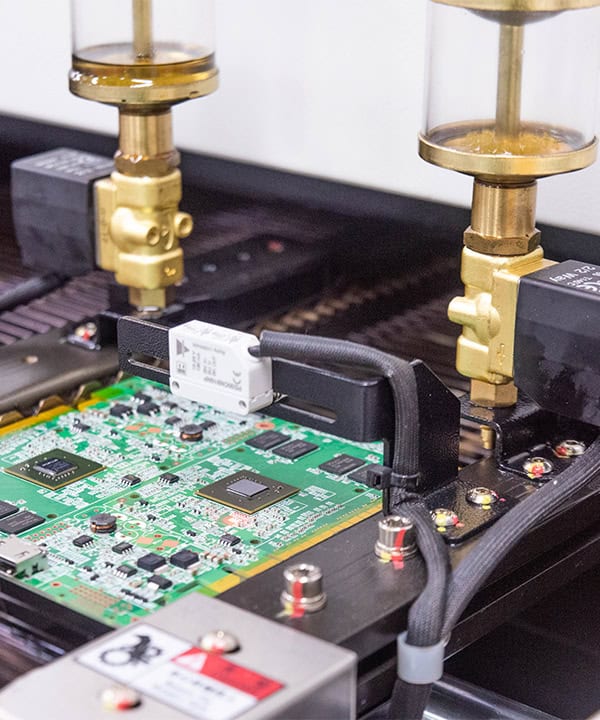

Advanced technology and equipment

We have advanced equipment for precise placement and soldering of BGA components, ensuring high precision and quality of assembly.

02.

Omnis Repreh

Our engineers have rich experience in BGA assembly and can provide professional technical support and solutions to ensure the successful implementation of each project.

03.

Strict quality control

We implement a strict quality management system, from raw material inspection to final product testing, to ensure high reliability and long-term stability of BGA PCB assembly.

04.

Omanis Competitive price and efficiency

By optimizing the production process and cost management, we are able to offer competitive price and faster delivery time while ensuring high quality.

BGA PCB Assembly Services

Design Evaluation and DFM Analysis

Prior to assembly, the PCB design is evaluated and DFM analyzed to ensure that the BGA components are compatible with the PCB board and that the design meets manufacturing standards.

Material Procurement

Procurement of BGA chips and other components according to the BOM (Bill of Materials).

BGA Placement

Precision placement machines are used to accurately place the BGA chips in the specified locations on the PCB.

Reflow Soldering

The BGA chips are held in place by a reflow soldering process. This process requires precise temperature control to ensure solder joint formation and reliability.

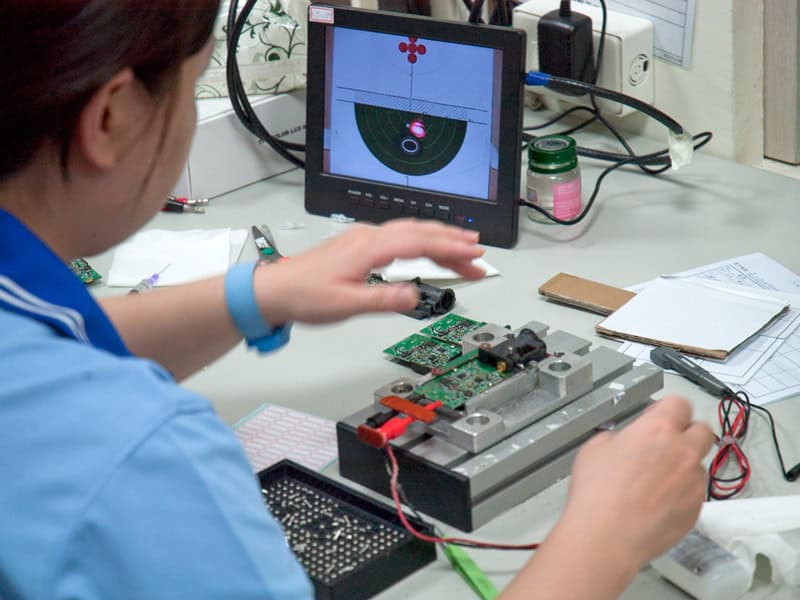

X-ray Inspection

Since the BGA solder joints are underneath the chip and not directly observable, X-ray inspection techniques are used to check the quality of the soldering.

Repair and Rework

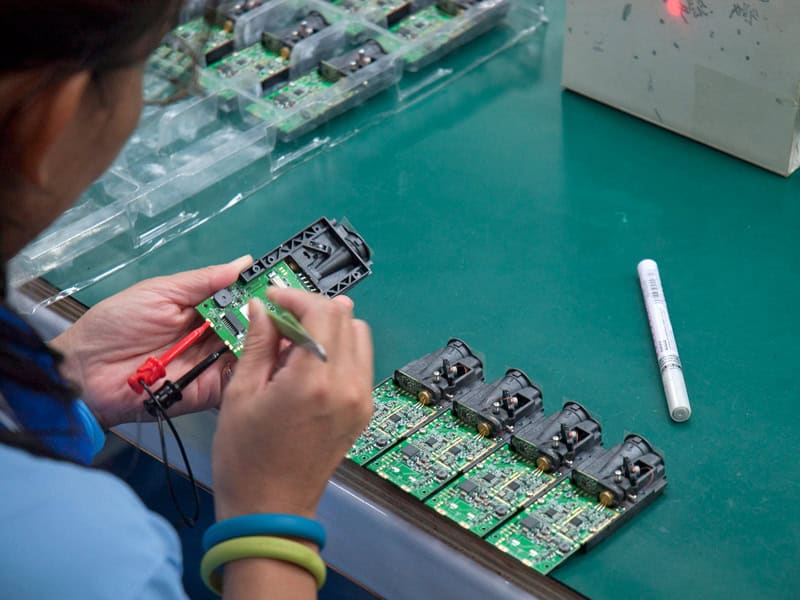

If faulty BGA solder joints are found, repair or rework them as necessary.

Assembly Test Flow

Automated Optical Inspection (AOI)

"Used to check the quality of soldering around BGA assemblies and the accuracy of component placementand accuracy of component placement."

Functionality Testing

"Electrical testing is performed to verify the functionality of the PCB and to ensure that all circuits are working as designed."

Non-Destructive Testing (NDT)

"Uses X-ray inspection or other advanced non-destructive testing methods to evaluate hidden defects under the BGA solder joints, such as the quality of the formation of spherical solder joints and possible short or broken circuits."

Environmental Testing

"May include temperature cycling, vibration testing, and humidity testing to evaluate the performance and reliability of the PCB under various environmental conditions."

Final Visual Inspection

"A final inspection performed at the end of the entire assembly process to ensure that nothing has been missed."

Sample Validation

"Thorough testing and validation of samples to ensure that they fully comply with design specifications before starting mass production."

Advantages of BGA PCB Assembly

High Density Connections

BGAs offer higher pin densities than traditional pin packages, allowing more connections to be realized in less space.

Better Electrical Performance

The BGA design reduces wire length, resulting in lower inductance and capacitance and improved signal integrity.

High Reliability

BGA solder joints are on the bottom of the chip and are less susceptible to thermal stress, making them more reliable than traditional pin packages.

Lower Failure Rates

The design of BGA solder joints reduces the risk of short circuits and breaks, increasing the success rate of assemblies.

Better Thermal Performance

BGA packages help conduct heat from the chip more efficiently, contributing to better overall device performance and stability.