Flex PCB

Flexibility

Light weight and compact size

High reliability and durability

Good vibration resistance

Thermal management

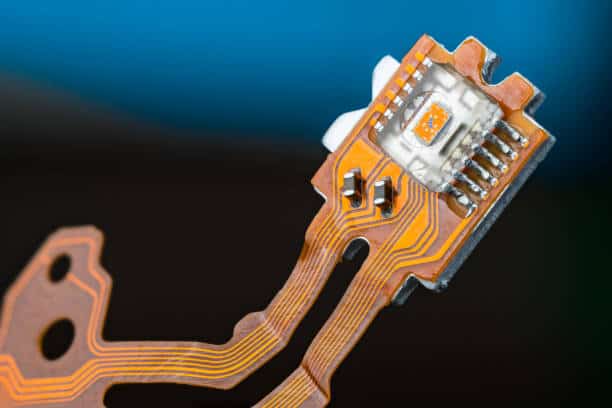

What is a flexible circuit board

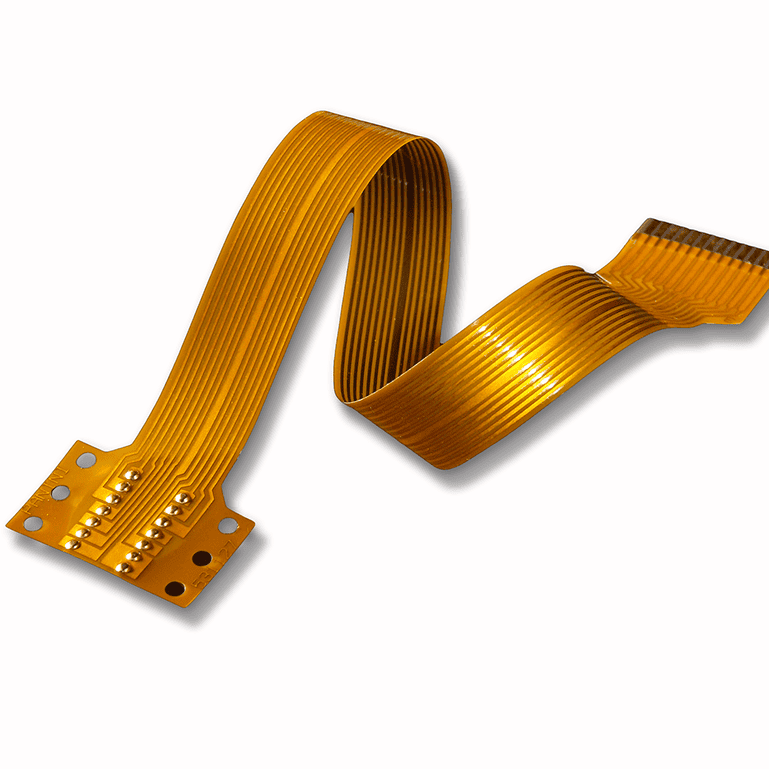

Flexible Printed Circuit board (FPC) is a printed circuit board made of polyimide or polyester film as a substrate. It has the characteristics of high wiring density, light weight, thin thickness and good bending.Flexible plate is mainly divided into: single-sided, double-sided, multi-layer flexible plate and rigid flexible plate four kinds:

the cost of single-sided flexible plate is low, and the electrical requirements are not high. In single-sided wiring, single-sided flexible plates are often used.

The double-sided flexible plate is a conductive pattern made of a layer etched on each side of the insulating base film, and the metallized hole connects the pattern on both sides of the insulating material into a conductive path to meet the design and use function of flexure.

multi-layer flexible plate is to layer 3 or more layers of single-sided or double-sided flexible circuit together, through drilling, electroplating to form a metallized hole, forming a conductive path between different layers. Multilayer circuit has better reliability, thermal conductivity and convenience.

Rigid flexible plate is composed of rigid and flexible substrate pressed together by selective strata. The structure is tight, forming conductive connections with metallized holes. To make a printed board have components on the front and back, rigid flexible plate is a good choice.

The production process of the flexible circuit board

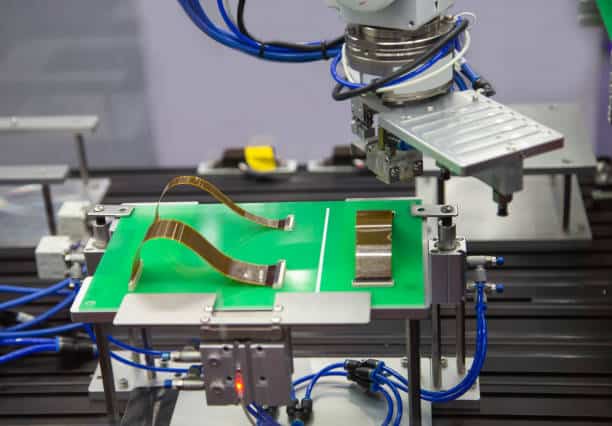

opening → punching and drilling→ removing glue slag copper plating →graphic transfer → etching and film removal →film protection →pressing →surface treatment → text production→electrical testing

Why Choose Us

01

Manufacturing Technology

We use the latest equipment, manufacturing technology and high quality materials.

02

Design Capability

We can design and customize flexible board PCBs according to customers' specific needs.

03

Quality Control

We guarantee that each piece of flexible board PCB meets the high standard of quality.

04

Engineering Team

A team with rich expertise to provide professional design and technical support.

05

Fast Delivery

able to complete production and delivery in a short period of time.

Areas of Application

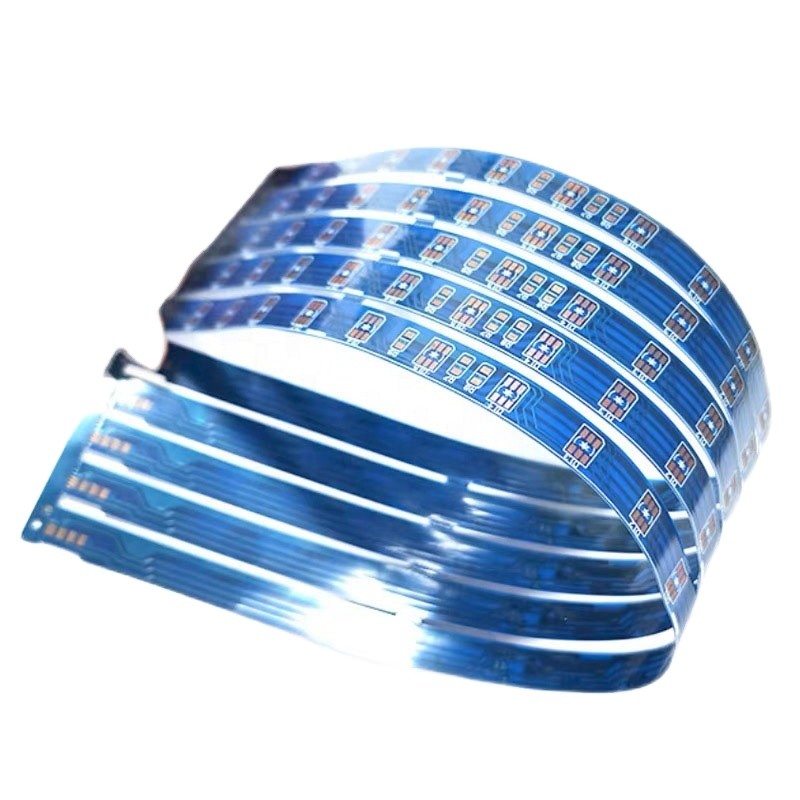

- Application Field Intelligent Terminal

- Wearable Electronics

- Consumer Electronics

- Automotive

- Medical

- Industrial Control Field

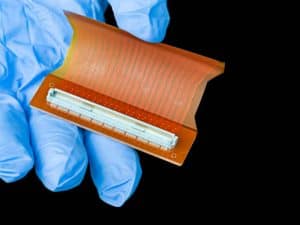

Flex PCB Specification at LHD Technology

| Number of layers | 1-6 |

|---|---|

| Finished board thickness (thinnest) | 3 mil (0.08mm) |

| Minimum Hole Diameter | 4 mil (0.10mm) |

| Minimum line width/spacing | 2 mil (0.05mm) |

| Maximum Board Size | 10" x 45" (250x 1200mm ) |

| Surface Finish | OSP, tin spray, electro-nickel/gold, electroless nickel/gold, lead-free tin spray, immersion gold. |

| Insulation resistance | ±1011Ω (Normal Normal) |

| Processing materials | polyimide ( PI ), polyester ( PET ), polyimide ( PI ) + FR4 |

Related Products