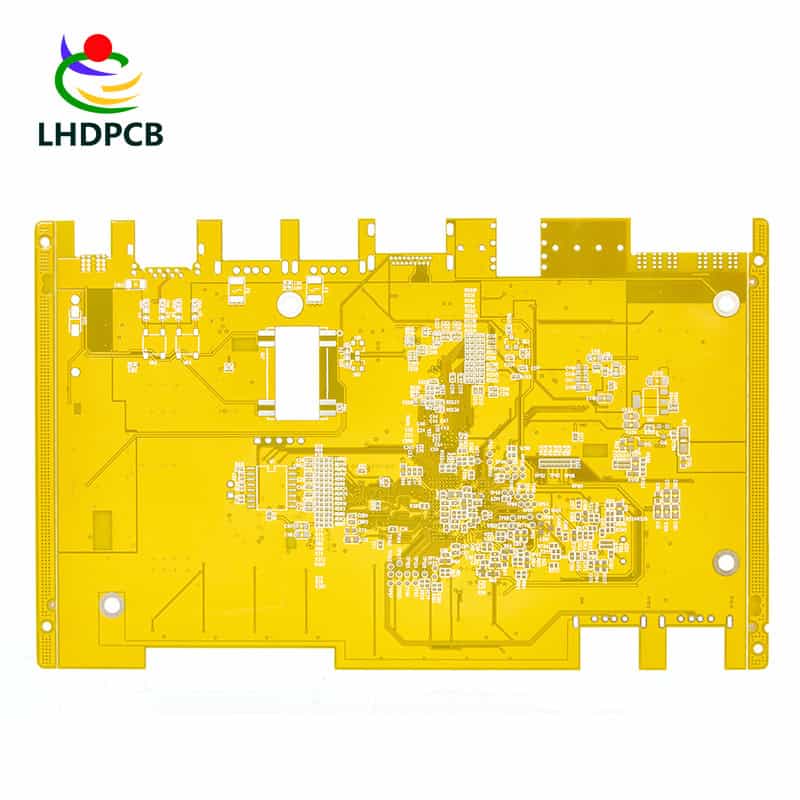

FR-4 PCB

What is FR-4 PCB?

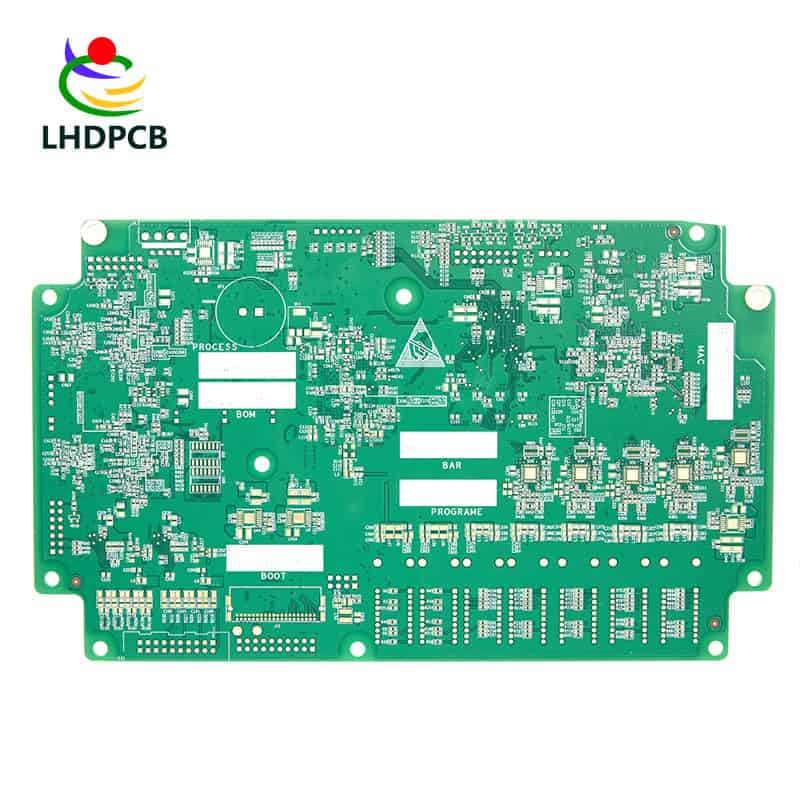

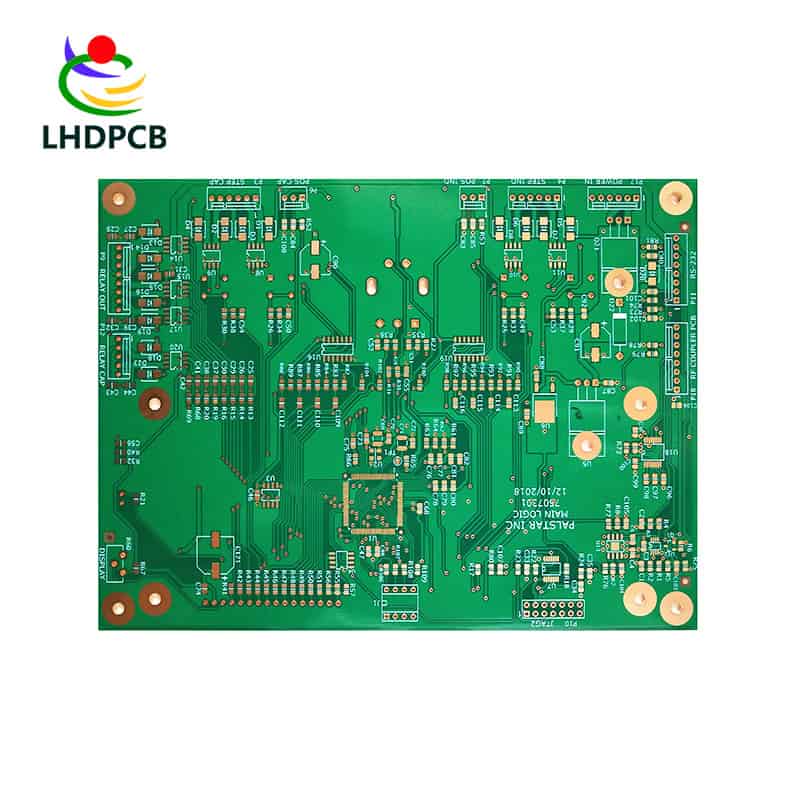

FR-4 PCB is a type of printed circuit board widely used in the electronics industry.

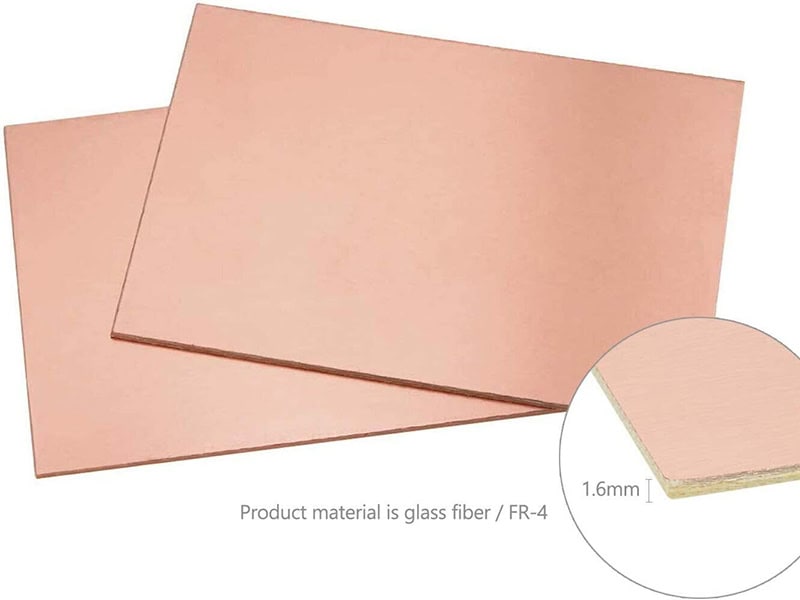

At LHD Tech, we understand the importance of a reliable printed circuit board for businesses dealing in electronics manufacturing. FR-4 refers to Flame Retardant (Flame Retardant) Class 4 material, which consists of glass fibers and epoxy resin, and is considered to be the standard substrate material in circuit board manufacturing.

That’s why offer high-quality FR4 PCB board products in bulk for our business partners. Our FR4, or flame-retardant grade FR4, laminate material is widely recognized for its exceptional balance of electrical properties, mechanical strength, and cost-effectiveness. This makes our FR4 PCB board one of the most popular choices among our business partners.

FR-4 material is made of glass fiber cloth and epoxy resin composite, with high strength, high rigidity and flame retardant. Among them, the glass fiber cloth is responsible for enhancing the mechanical strength and stability of the circuit board, and the epoxy resin provides good insulation properties and high temperature resistance. Its strength, stability and supply chain maturity make it one of the most widely used materials in PCB manufacturing.

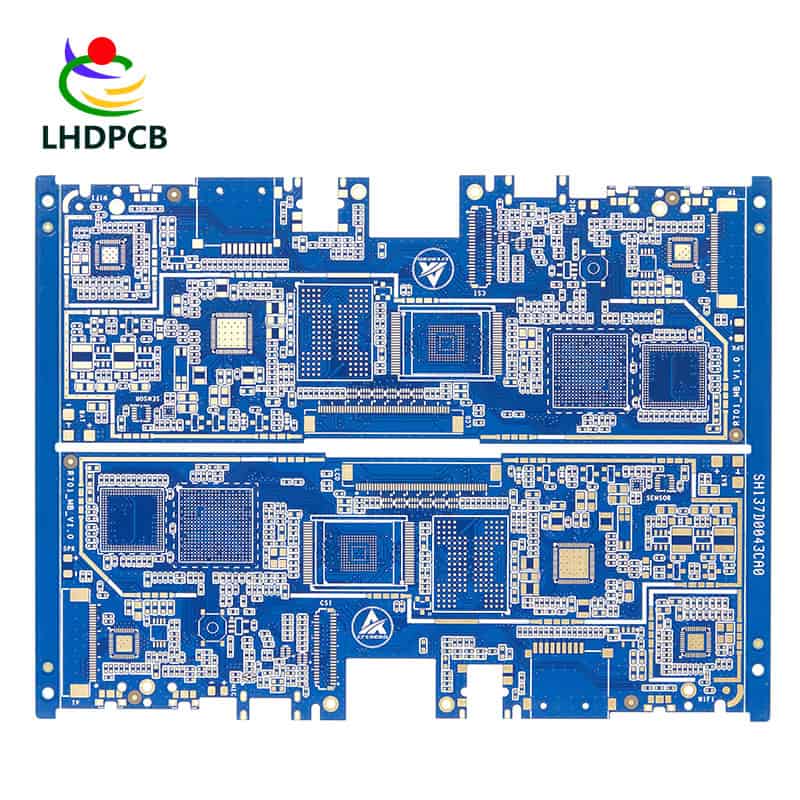

The most obvious difference between FR-4 materials is the Tg value, according to the Tg temperature, FR-4 plates are generally divided into low Tg, medium Tg and high Tg plates.In the industry, FR-4 Tg of about 135℃ is usually classified as low Tg sheet; The FR-4 of Tg at about 150℃ is medium Tg plate; FR-4 Tg at about 170℃ is classified as high Tg plate.If the PCB is processed with more times of pressing, or more PCB layers (more than 14 layers), or the welding temperature is high (≥230 ° C), or the working temperature is high (more than 100 ° C), or the welding thermal stress is large (such as wave welding), high Tg plate should be selected.

Why Choose LHD Tech

Quality Assurance

Our strict quality control systems and advanced manufacturing equipment ensure each FR-4 PCB meets high-quality standards, ensuring stable and reliable product performance. FR4 is a readily available and relatively inexpensive material compared to some high-performance alternatives.

Innovation and Customization

We stay at the forefront of PCB manufacturing technology, offering customized solutions to meet specific requirements. Whether it's complex multi-layer designs or specialized surface treatments, we provide expert support.

Cost-Effectiveness

By optimizing production processes and employing automated equipment, we offer competitively priced FR-4 PCB without compromising quality, helping clients reduce production costs and enhance market competitiveness.

Timely Delivery

We prioritize production efficiency and delivery times, ensuring fast turnaround times even for large orders or complex custom requests, and meeting urgent market demands. This makes it an ideal choice for projects requiring a balance between functionality and budget.

Superior Performance

FR4 TG offers excellent electrical insulation properties, making it suitable for various electronic circuits. Its low dielectric constant and loss tangent ensure efficient signal transmission, minimizing signal distortion and noise.

Durability and Reliability

FR4 TG boasts outstanding dimensional stability and moisture resistance. This translates to FR4 PCBs that can withstand demanding environments and high temperatures, ensuring long-lasting performance for your devices.

Your Trusted FR4 PCB Board Manufacturer:

At LHD Tech, we are committed to providing exceptional quality and versatility in FR4 PCB board manufacturing. We offer a wide range of FR4 TG options, including TG 135°C, TG 150°C, and TG 170°C, to cater to the specific thermal demands of your application.

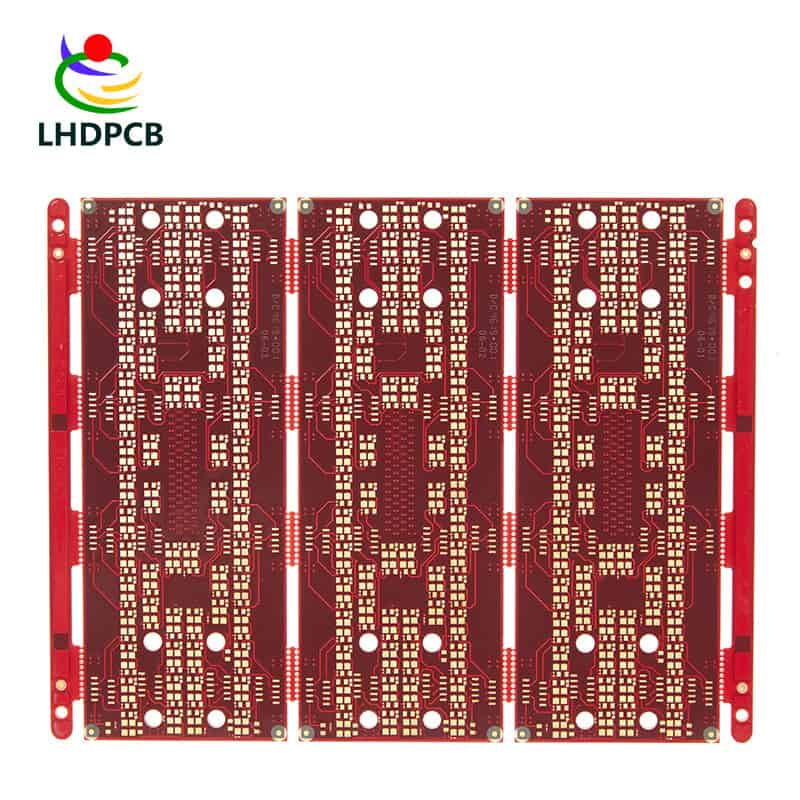

Our advanced production capabilities allow us to manufacture FR4 board designs in various layer counts, thicknesses, and hole sizes. This extensive customization ensures you receive FR4 PCBs that perfectly match your design requirements:

Multi-Layer Expertise: Need complex, high-density circuits? We offer multi-layer FR4 PCB production capabilities, allowing you to pack more functionality into a smaller footprint.

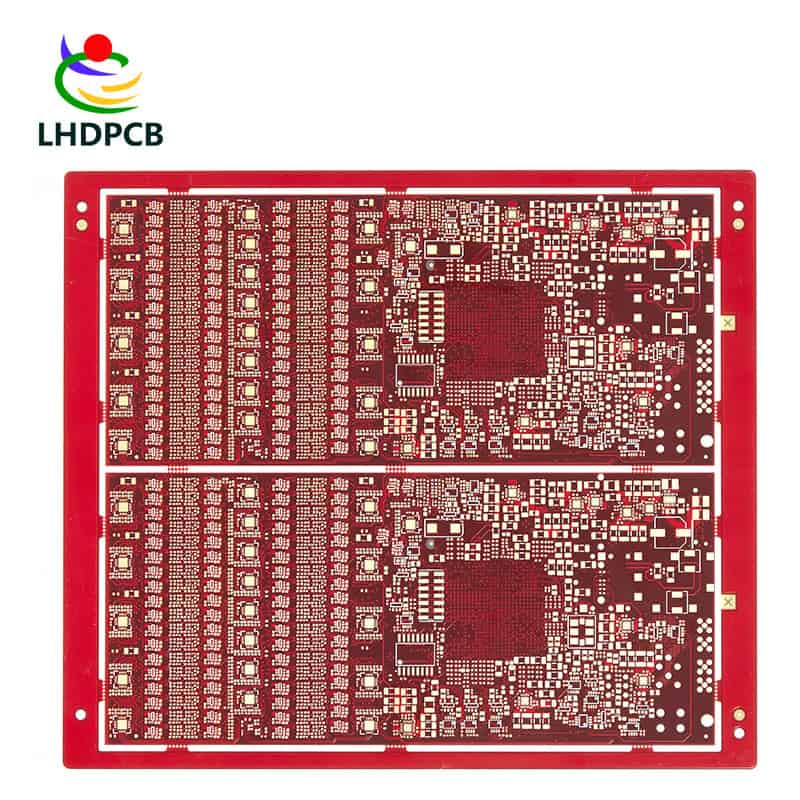

Precise Dimensions: Our state-of-the-art equipment guarantees precise drilling and routing, ensuring accurate dimensions and reliable electrical connections on your FR4 board.

Flexible Ordering: We cater to businesses of all sizes, accommodating both large-volume production runs and smaller orders for prototypes or low-volume projects.

LHD Technology FR-4 Production Capacity

Related Products

| Processing layers | 1-48 layers |

|---|---|

| Finished board thickness (thinnest - thickest) | 0.008″ ~ 0.24″ (0.20mm ~ 6.0mm) |

| Minimum Hole Diameter | 6mil (0.15mm) |

| Minimum line width/spacing | 3-4 mil (0.076-0.10mm) |

| Maximum board size | Single and double layer 22″x 43″ (550 x 1100mm) Multilayer 22″x 25″ (550mm x 640mm) |

| Impedance control | ± 10% |

| Surface treatment process | oxidation resistant OSP, tin spraying, electric nickel/gold, chemical nickel/gold, lead-free tin spraying, gold finger, immersion silver, immersion tin, thick nickel/gold. |

| Processing materials | FR4 (Sangyi, KB, International), high TG (TG150, TG170), halogen-free plates, high-frequency plates (Rogers, Teflon, Taconic), domestic PTFE (F4B, F4BK),, aluminum substrate (Berquist, domestic Al-based), copper-based, iron-based, ceramic substrate. |

Applications for FR4 PCB Board

The versatility of FR4 PCBs makes them suitable for a wide range of electronic applications, including:

From smartphones and laptops to tablets and gaming consoles, FR4 is a mainstay in modern consumer electronics.

Industrial control systems, automation machinery, and medical devices often rely on the durability and reliability of FR4 PCBs.

Routers, switches, and other telecommunication equipment benefit from the high-performance characteristics of FR4 board.

The added flexibility and thin design makes FR4 PCB board a vital component for manufacturing of new energy products.

Strictly control each process to ensure quality

Cutting room

Cut according to the Gerber file size

Inner layer

Plan the power/ground layer for multi-layer boards, mainly used to arrange power lines and ground lines

AOI

Automatic optical inspection to ensure product quality.

Lamination

"Heat and pressure" make PP combined with different inner core boards and outer copper foils for manufacturing

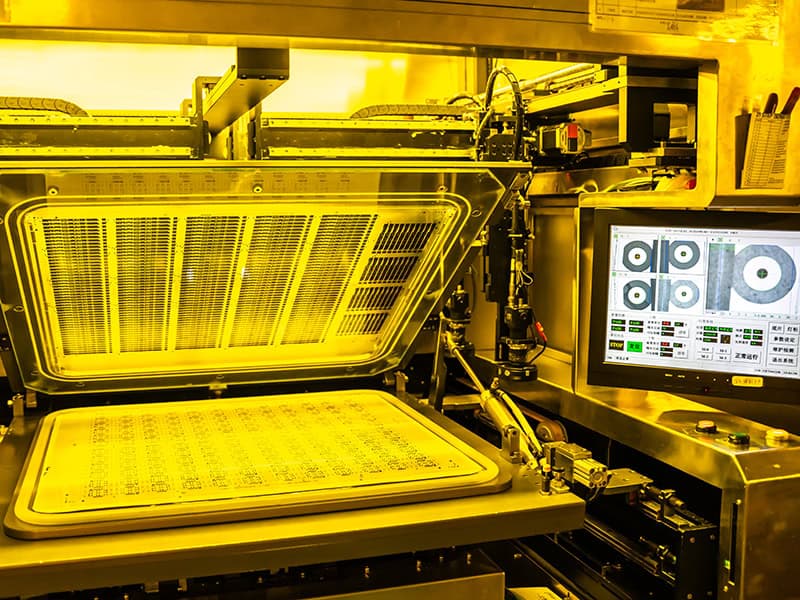

Line exposure

Transferring circuit design patterns to PCB substrate

Soldermask

A layer of insulating material applied to the surface of a PCB to protect the conductive paths of the circuit board.

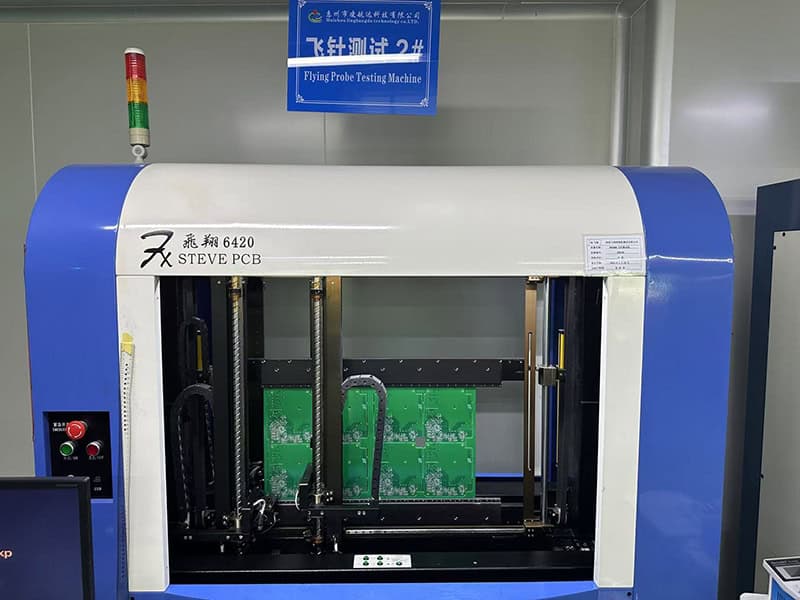

E-testing

PCB testing is to ensure the quality and performance of circuit boards.

Drilling

Check the Gerber file to determine the hole diameter for drilling

Plating

Improve the conductivity, mechanical strength and welding performance of PCB

Silkscreen

Print information such as text, symbols and graphics on the PCB surface

FQC

Perform visual inspection on PCB to ensure it meets design requirements and customer standards

Electroless plating copper

A layer of copper is deposited on the hole wall of the PCB to make the hole wall conductive.

Outer layer etching

Remove excess copper to form the desired circuit pattern

Routing

Cut according to the size of the Gerber file

Vacuum packaging

Put in humidity strips and desiccant to vacuum pack the PCB

LHD Never Leaves Problems for Customers to Solve. It’s a Principle We Stand By!

Why Choose US For Your FR4 PCB Needs

Are you ready to let LHD Technology customize FR-4 PCB for you?

When it comes to FR4 PCB boards, we at LHD Tech are your one-stop shop for quality and reliability. Our commitment to precision manufacturing, diverse capabilities, and competitive pricing make us the ideal partner for all your FR4 PCB requirements.

Please feel free to contact us today to discuss your requirements or any queries related to our services and pricing.