Prototype PCB Assembly

Prototype PCB Assembly

Through LHD Technology Prototype PCB Assembly service, we deliver the fastest within 24 hours

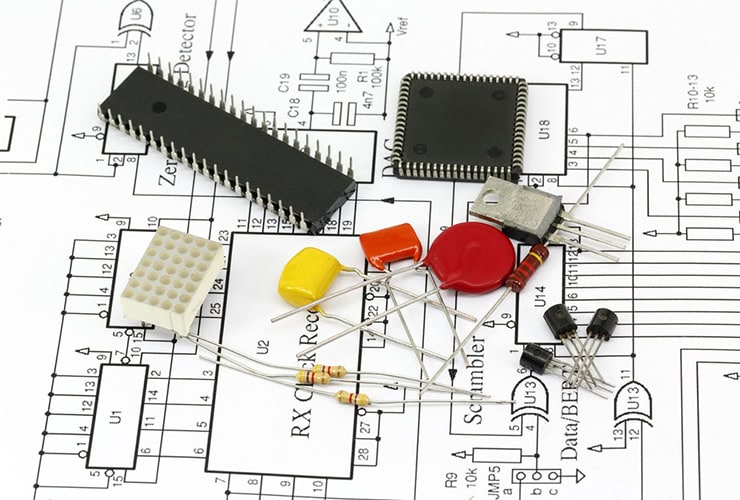

Component Sourcing

We have a complete and stable supplier system to provide high quality components for each of our projects.LHD also has a professional purchasing team with in-depth knowledge of the market to ensure that we can provide our customers with the components they need at competitive prices.

Engineering

Before starting to manufacture the PCB assembly prototype, engineers will perform DFM analysis and send EQ confirmation to ensure that there are no manufacturing issues. We will provide one-on-one service to our customers to ensure the quality of our products.

Assembly

SMT assembly

DIP plug-in

Manual assembly

welding

Cleaning and inspection

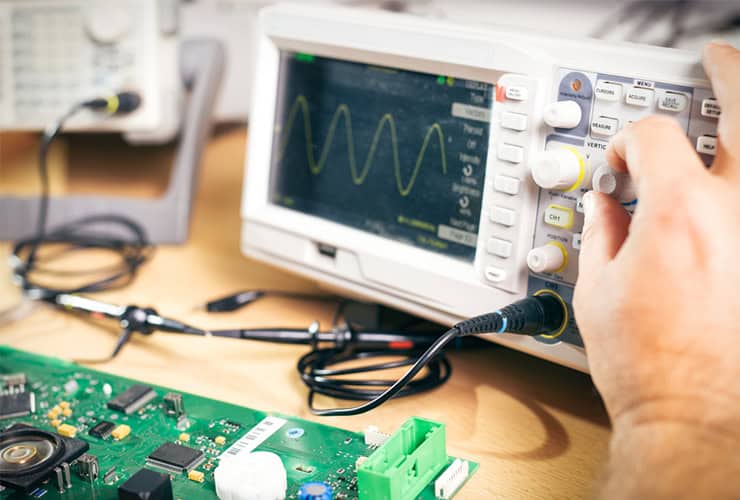

Test

Functional testing: Verify whether the function of the prototype PCB meets the design requirements.

Electrical Testing: Perform necessary electrical tests such as insulation and continuity testing.

Fault diagnosis and repair: If problems are found during testing, fault diagnosis and necessary repairs will be made.

Ship

Final Inspection: Final quality inspection before shipment.

Packaging: Proper packaging as per customer requirements to protect the prototype board.

Logistics arrangements: arrange appropriate logistics to ensure that products are delivered to customers on time and safely

Why Choose Us

Advanced Technology and Equipment

Using advanced technology and equipment for prototype PCB assembly, LHD is able to handle a wide range of complex design requirements and ensure high quality products.

Quality Assurance

LHD implements strict quality control measures for each project, from raw material inspection to final product testing, to ensure that prototype PCBs meet high standards.

Customized Service

We are able to provide customized service according to the specific needs of customers, whether it is a small batch or special requirements of the prototype PCB, we can accurately meet.

Experienced

With rich industry experience and successful cases, we are able to provide customers with a full range of services from design, assembly to testing.

Cost-effective

Provide competitive pricing without sacrificing product quality and performance through effective process management and optimization.

Excellent Customer Service

Provide comprehensive customer support, including project management, technical consulting and after-sales service, to ensure that every customer need is met.