SMT Assembly

SMT Assembly

At LHD Technology, we have a professional team, equipment and can produce a wide variety of electronic products to meet the assembly needs of our customers.

One-stop SMT assembly service

Material Inspection

Solder Paste Printing Inspection

IPQC Check Materials

SMT First Article Testing

Inspection of DIP Plug-in Process

QA Full Shipment Inspection

Why Work with Us for SMT Assembly?

Efficient Production line

LHD has advanced production equipment and automation technology, which enables it to fulfill large-volume orders quickly and efficiently while ensuring product quality.

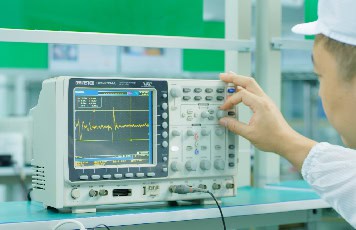

Strict Quality Control

Through a strict quality management system, we ensure that each component installation meets the highest standards, reducing the possibility of errors and rework.

Technical Support and Customer Service

Professional technical team and customer service staff can provide professional consultation and support to ensure that customers' needs are quickly responded to and resolved.

Technical Support and Customer Service

Professional technical team and customer service staff can provide professional consultation and support to ensure that customers' needs are quickly responded to and resolved.

Cost-effective

through optimizing the production process and bulk purchasing, we are able to provide customers with competitive prices while guaranteeing product quality.

Rich Industry Experience

years of industry experience and successful cases, able to provide customers with the best practices and experience sharing in the industry.

Our PCB SMT Assembly Capacity

| SMT Lines | 7 Lines |

|---|---|

| Capacity | 8 Million Placements Per Day |

| Max Board Size | 680*550mm Smallest:0.25"*0.25" |

| Min Components size | 0201-54 sq.mm (0.084 sq.inch),Long Connector,CSP,BGA,QFP |

| Speed | 0.15sec/chip, 0.7sec/QFP |

| File Formats | Bill of Materials ,Gerber Files,Pick-N-Place Files(XYRS) |

| Testing | XRAY Inspection,AOI Testing ICT,Flying Probe,Burn-in,Function Test |

LHD Technology Assembly Process

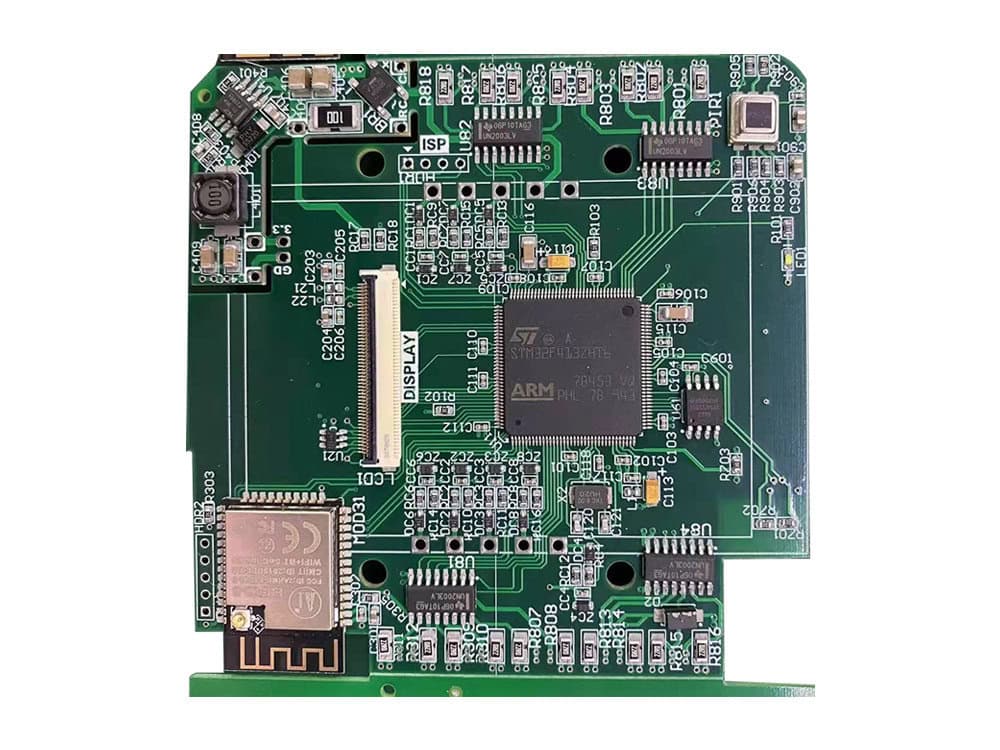

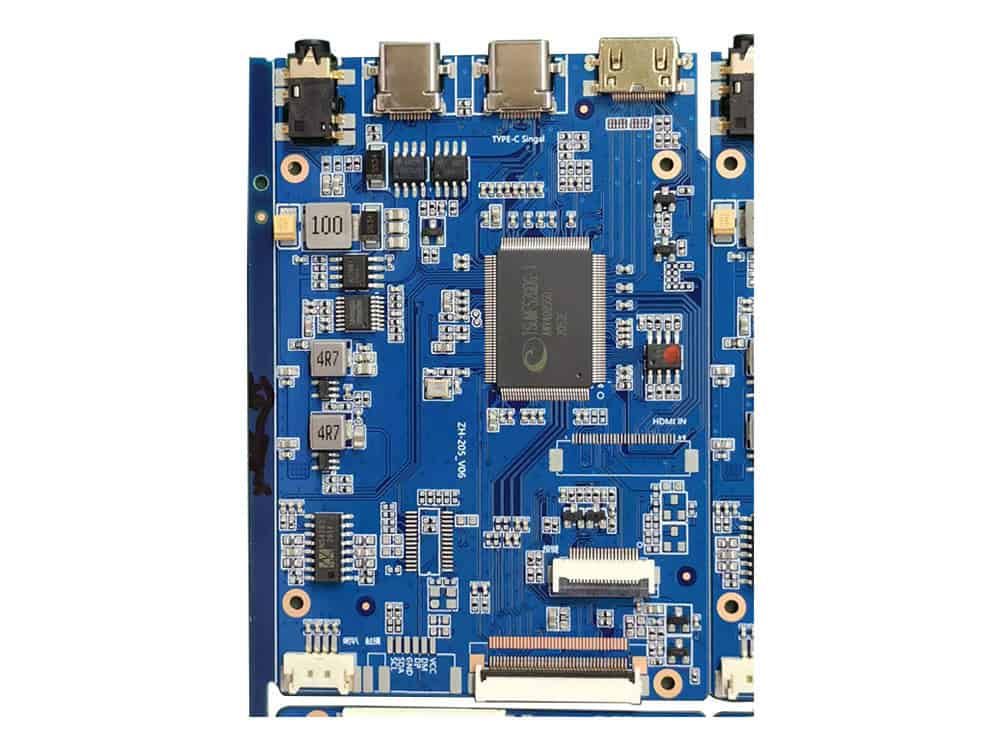

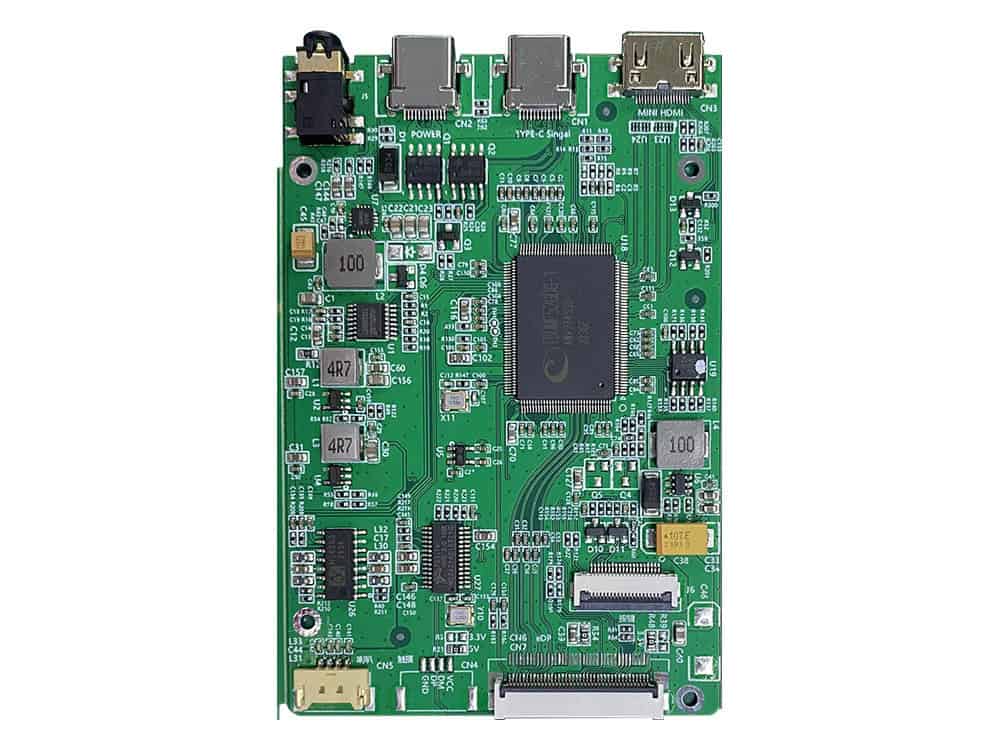

LHD assembly case