Solder Mask

Home > Solder Mask

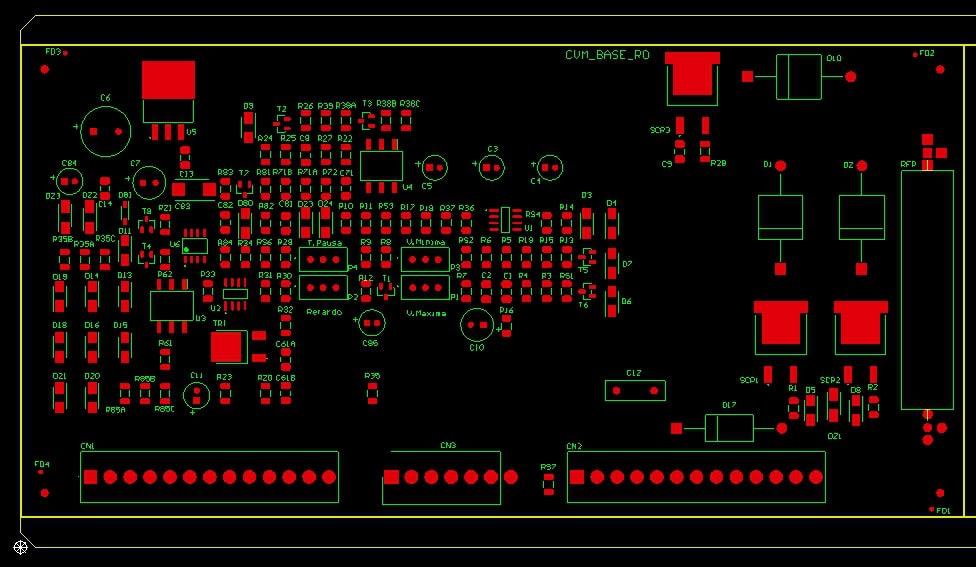

What is PCB solder mask

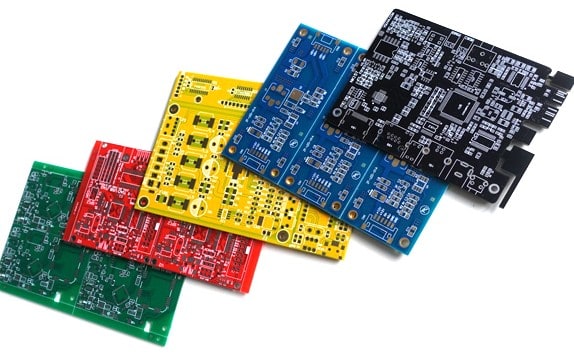

PCB solder mask is a protective coating, usually made of polymer material, applied to the surface of copper conductors on a printed circuit board (PCB). Its main function is to prevent oxidation of copper conductors, avoid solder bridges during soldering, and provide electrical insulation. The solder mask is usually green, but can also be other colors such as red, blue, and black.

Common solder mask colors for LHDPCB include: black, blue, yellow, red, green. Of course, if you need to customize other colors, we can also manufacture

The main roles of solder mask in PCB include

Prevent oxidation

Protect copper conductors from environmental influences and extend the service life of the circuit board.

Prevent oxidation

Protect copper conductors from environmental influences and extend the service life of the circuit board.

Avoid solder bridges

Reduce the risk of short circuits caused by excess solder by covering areas that do not need soldering.

Prevent oxidation

Protect copper conductors from environmental influences and extend the service life of the circuit board.

Prevent oxidation

Protect copper conductors from environmental influences and extend the service life of the circuit board.

Common PCB solder mask types include:

Epoxy liquid solder mask

Applied through screen printing process, low cost, suitable for most applications.

Dry film photoimageable solder mask (DFM)

Dry film is applied to PCB through vacuum lamination process, suitable for applications with high precision requirements.

Liquid photoimageable solder mask (LPI)

Using photosensitive materials, it can be applied by spraying or screen printing, with high precision and surface flatness.

Top and bottom masks

Used to mark the opening positions of the top and bottom of the PCB, respectively, to facilitate the subsequent soldering of components.

Difference between solder mask and soldering layer

Although both solder mask and soldering layer are related to the soldering process of PCB, their functions and applications are different:

Solder mask:

refers to a protective film applied on PCB to prevent solder from being applied to unwanted locations. It allows component pins to be soldered by opening windows in specific areas.

Solder layer (flux)

is a material used in the surface mounting process, usually used to improve the quality of soldering. Flux helps clean the metal surface and promote solder flow, thereby improving the strength of the connection.