Printed Circuit Boards (PCBs) are the backbone of modern electronics, serving as the foundation for countless devices and systems. At LHD TECH, we understand the critical role that PCB testing plays in ensuring optimal performance, reliability, and safety. In this article, we explore the diverse benefits of PCB testing, highlighting its role in maximizing efficiency, minimizing defects, and enhancing overall product quality.

Table of Contents.

ToggleThe advantages of PCB testing

Quality Assurance

Quality Assurance

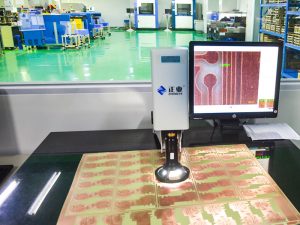

PCB testing plays a critical role in quality assurance at LHD TECH, helping us identify and rectify defects before products reach the market. By subjecting PCBs to comprehensive testing procedures, including electrical, functional, and performance tests, we can detect and resolve issues such as faulty components, short circuits, and incorrect connections. This proactive approach to quality control minimizes the risk of product recalls, warranty claims, and customer dissatisfaction, ultimately safeguarding our brand reputation and consumer trust.

Cost Reduction

Implementing PCB testing early in the production process can lead to significant cost savings over time. By identifying and addressing defects at the source, we can reduce the need for rework, scrap, and component replacement, thus lowering production costs and improving yield rates. Moreover, detecting potential issues before assembly or integration into larger systems helps prevent downstream failures and costly repairs, mitigating financial losses and maximizing profitability in the long run.

Enhanced Product Performance

Enhanced Product Performance

PCB testing ensures that electronic devices operate reliably and efficiently under various conditions. Functional testing verifies that all components and circuits perform as intended, confirming that the PCB meets specified performance criteria and standards. By validating functionality and performance parameters, such as voltage levels, signal integrity, and thermal management, we can deliver products that meet or exceed customer expectations for reliability, durability, and responsiveness.

Compliance and Standards Conformance

PCB testing is essential for ensuring compliance with regulatory requirements and industry standards. We must adhere to a myriad of regulations, including safety, electromagnetic compatibility (EMC), and environmental directives, to ensure product safety and legal compliance. Testing procedures, such as electromagnetic interference (EMI) testing and environmental stress screening (ESS), help verify that PCBs meet applicable standards and certifications, such as UL, CE, and RoHS, demonstrating adherence to quality and safety protocols.

Early Detection of Design Flaws

Testing PCB prototypes and pre-production samples at LHD TECH enables early detection of design flaws and performance limitations. Through techniques such as design for testability (DFT) and design for manufacturability (DFM), our engineers can optimize PCB layouts, component placements, and routing configurations to improve test coverage and facilitate troubleshooting. By identifying potential design issues upfront, we can streamline the development process, accelerate time-to-market, and minimize costly design iterations.

Continuous Improvement and Innovation

PCB testing provides valuable feedback for continuous improvement and innovation in product design and manufacturing processes. By analyzing test data, identifying trends, and implementing corrective actions, we can iteratively refine our designs, test methodologies, and production techniques to enhance product quality, reliability, and performance. This iterative approach fosters a culture of innovation and excellence at LHD TECH, driving advancements in PCB technology and pushing the boundaries of what is possible in electronic engineering.

Conclusively

Conclusively

At LHD TECH, we recognize that PCB testing is a critical component of modern electronics manufacturing, offering a multitude of benefits that extend beyond quality assurance. From cost reduction and compliance assurance to performance optimization and innovation, PCB testing enables us to deliver high-quality products that meet the demands of today’s competitive market. By investing in robust testing processes and leveraging advanced testing technologies, we can achieve greater efficiency, reliability, and customer satisfaction, positioning ourselves for success in the dynamic world of electronic engineering.

We are available for 24/7 customer support, Contact us!